Custom metal fabrication is changing industries with better quality work. It offers stronger and cheaper solutions made for specific needs. For example, custom welded items last longer than regular ones. This means fewer repairs are needed over time. Skilled welders and strict checks ensure they meet industry rules. This improves their overall value. Also, the metal fabrication market may grow to $893.3 billion by 2025. New tech like automation and AI help make this possible. These tools make metal fabrication key to industrial success.

Key Takeaways

Custom metal work makes strong parts designed for specific needs. This improves product quality.

Modern methods like exact welding and laser cutting cut down waste and errors. This saves time and money.

Custom designs help businesses stand out by offering special products that customers like.

Using machines and robots makes fabrication faster and improves product quality.

Spending on custom solutions fixes problems now and adds value later.

Understanding Custom Metal Fabrication in 2025

What Is Custom Metal Fabrication?

Custom metal fabrication means turning raw metal into useful parts. These parts are made to fit specific needs and uses. The process includes cutting, bending, and putting pieces together. Unlike regular methods, custom fabrication makes unique, high-quality items for special jobs.

Experts use tools like CAD software and welding to make precise parts. For example, custom welded items are stronger and last longer. This method improves quality and ensures the product fits your project perfectly.

Why Custom Fabrication Is Essential for Modern Industries

Custom fabrication is very important in industries like construction and energy. It helps solve problems that standard parts cannot fix. This flexibility allows businesses to create new ideas and meet tough challenges.

Lightweight metals like aluminum and titanium are in high demand. These materials are key in cars and planes because they are light but strong. Eco-friendly methods like laser cutting reduce waste and add value to the process.

The Growing Importance of Customization in Manufacturing

Customization is now a big part of modern manufacturing. It helps businesses adapt quickly to changes and customer needs. Custom solutions save time and lower storage costs.

Unique designs also make products stand out and attract buyers. Adding special features meets customer needs and increases value. As the industry grows, precision and customization will lead to more success.

Techniques That Add Value in Custom Metal Fabrication

Precision Welding for Stronger Structures

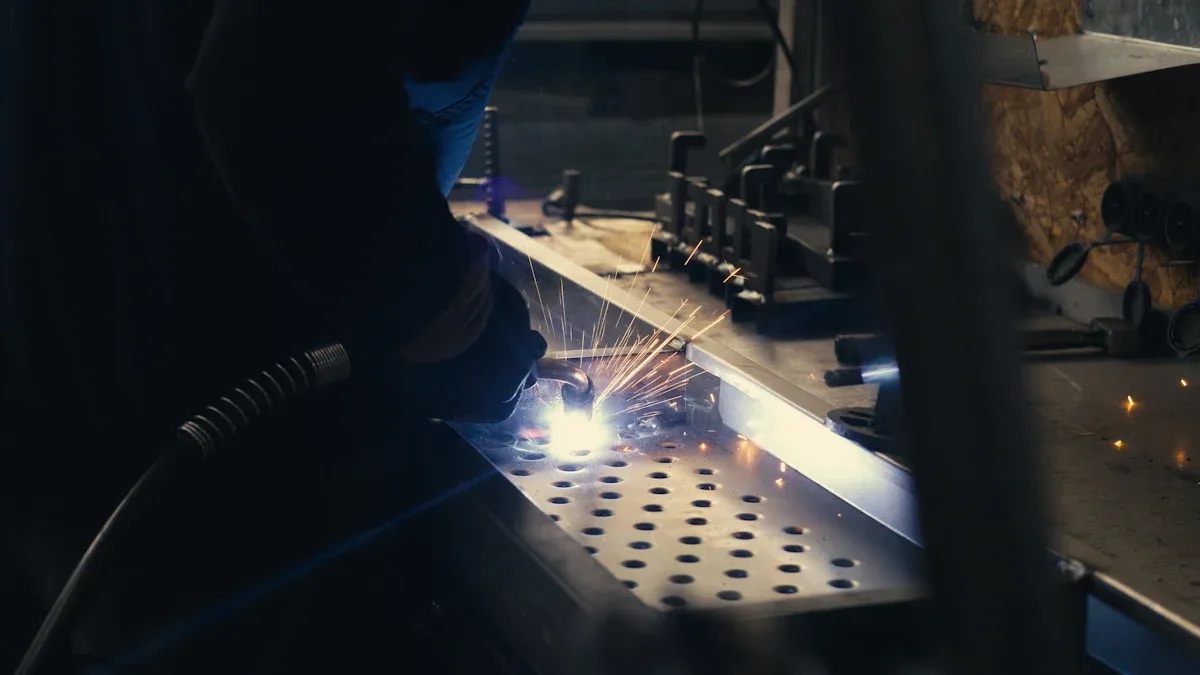

Precision welding helps make products strong and reliable. Advanced methods like laser beam welding (LBW) and friction stir welding (FSW) create strong metal bonds. These methods are great for industries like aerospace and construction. Robots improve welding by making it faster and more accurate. Certified welders use virtual reality (VR) training to meet industry rules. This ensures high-quality work and fewer risks of failure.

Advanced Cutting and Shaping Techniques

Cutting and shaping metal with tools like lasers and CNC machines is very precise. Laser cutting works well for thin materials and detailed designs. CNC machines handle heavy metals with great accuracy. These methods reduce waste and mistakes, saving time and money. Techniques like metal spinning and stamping also make smooth parts for industries like aerospace. Choosing the right method for your project improves results and efficiency.

Method | Benefits | Uses |

|---|---|---|

Laser Cutting | Very precise, fast, and makes clean cuts | Thin materials, detailed designs |

Metal Spinning | Accurate, smooth parts, used in many industries | Aerospace, lighting, industrial |

Advanced Stamping | Fast, customizable, and good for complex parts | Manufacturing in various fields |

Finishing for Strength and Looks

Finishing methods make products last longer and look better. Powder coating and anodizing protect against rust and damage. These finishes also improve how products work, like making them resist chemicals. Polished surfaces make products more attractive to buyers. Investing in good finishing adds value and helps products stand out in the market.

Tip: Finishing not only makes products stronger but also makes them look better, which attracts more customers.

The Benefits of Custom Fabrication for Businesses

Custom Solutions for Specific Industry Needs

Custom fabrication helps businesses make parts that fit perfectly. Unlike standard parts, custom ones work better and save time. For example, industries like aerospace and cars need custom parts for safety. Working with skilled fabricators makes sure designs are strong and useful.

This method solves special problems in different industries. Fabricators listen to your needs and create smart solutions. By making parts just for your work, you get better results. Custom fabrication fixes problems now and adds value for the future.

Improving Efficiency and Cutting Costs

Custom fabrication makes work faster by creating parts for exact jobs. This reduces delays and increases productivity. Tools like CNC machines and CAD software make designs accurate. This lowers mistakes and saves materials.

Using custom fabrication also helps with just-in-time production. You only make what you need, saving storage space and money. Strong finishes make products last longer, cutting repair costs. These savings help your business spend less and work better.

Standing Out with Unique Products

In a crowded market, being different is important. Custom fabrication lets you make special products that stand out. By meeting customer needs, you build trust and show quality.

Custom fabrication also helps you keep up with trends. Using light materials or green methods keeps you ahead. This flexibility improves your brand and keeps customers happy. Choosing custom fabrication helps your business stay strong and valuable.

How Technology Is Changing Custom Metal Fabrication

The Role of Automation and Robotics

Automation and robots are making custom metal fabrication better. Cobots, or helper robots, work with people to improve speed and accuracy. These robots do simple tasks, so workers can focus on harder jobs. Machines with automatic tools and material systems save time and reduce mistakes.

Robots also make work more precise with advanced tools. Automated systems do jobs like welding and assembly with great consistency. AI helps by predicting problems and checking for defects. Adding robots to your work makes things faster and results better.

Improvements in Laser Cutting and CNC Machining

New laser cutting and CNC machining methods have changed metal fabrication. Strong lasers, like the GX-F ADVANCED series, use AI to work smarter and waste less. These lasers cut with precision, perfect for detailed designs and thin materials.

CNC machines give exact control over tasks. They create complex shapes based on digital plans. This ensures products match your needs perfectly. Automation in these tools reduces delays and speeds up production, helping you meet deadlines.

Topic | Details |

|---|---|

High-Powered Lasers | Smart lasers use AI to work better and save resources. |

Enhanced Efficiency | Automation cuts downtime and speeds up production, showing how tech improves fabrication. |

Smart Manufacturing and Data-Driven Processes

Smart manufacturing uses data to improve custom metal fabrication. Advanced software helps make accurate designs, reducing mistakes and saving time. CNC machines and robots handle repeated tasks, boosting productivity and quality.

Precise methods like laser and waterjet cutting reduce waste and speed up work. 3D printing, or additive manufacturing, creates complex shapes while saving energy and materials. These tools let you make custom solutions that fit your needs, keeping your work competitive.

Note: Smart manufacturing not only makes work faster but also saves money and helps the environment.

Custom metal fabrication helps businesses improve quality and add value. Methods like precise welding, advanced cutting, and expert finishing make products better. Using tools like CAD software and CNC machines reduces mistakes and speeds up work.

Custom designs solve special problems and help you stand out.

Spending on custom-made machines saves money and boosts efficiency.

Examples show how smart planning and new methods bring big rewards. For instance:

Changing metal parts lowers costs when metal prices go up.

Trying new fabrication methods saves money in the long run.

Spreading out tooling costs helps manage money and grow production.

By using custom welding and other special techniques, your business can succeed. Now is the best time to choose custom metal fabrication to stay ahead and find new chances.

FAQ

What are the most common metal fabrication techniques used today?

Metal fabrication uses cutting, welding, bending, and shaping methods. Advanced tools like lasers and CNC machines make work precise. These methods create strong, high-quality parts for specific needs.

How does custom metal fabrication improve product quality?

Custom fabrication makes parts that fit exact needs perfectly. Techniques like precise welding and expert finishes make them stronger. This means products last longer and work better.

Can custom metal fabrication reduce costs for businesses?

Yes, custom fabrication saves materials and reduces mistakes. Tools like CNC machines and lasers make production faster. This lowers costs while keeping products high-quality.

What industries benefit most from custom metal fabrication?

Industries like aerospace, cars, and construction use metal fabrication a lot. They need strong, light, and exact parts. Custom fabrication meets these needs well.

How is technology shaping the future of metal fabrication?

Robots, automation, and smart tools are changing metal fabrication. These tools make work faster, more accurate, and more efficient. Businesses using them stay ahead in the market.