Metal shaping is very important for new ideas in industries, especially when considering the future of metal fabrication. It has a huge financial impact, worth about 639.62 billion USD in 2023. North America alone generated 215.0 billion USD and might reach 347.5 billion USD by 2032. This indicates a growing demand for shaped metals in cars and airplanes.

New tools are transforming how metal shaping works, which is crucial for the future of metal fabrication. Robots, smart computers, and 3D metal printing make work faster and more personalized. Digital twin tools and IoT assist by monitoring and resolving issues quickly. Keeping up with these advancements is essential to remain competitive in expanding markets.

Key Takeaways

Metal fabrication is growing fast and may reach $639.62 billion in 2023. Knowing new trends helps businesses succeed.

Automation and smart tools make work faster. Robots and AI can improve productivity by 30% and lower mistakes.

3D printing cuts waste and speeds up making things. This eco-friendly way helps the planet and meets market needs.

IoT lets machines be watched in real-time. It cuts downtime and predicts repairs, saving money.

Training workers is very important. Teaching new skills keeps workers ready for modern challenges.

Key Trends in Metal Fabrication

Automation and Smart Manufacturing

Automation is changing how metal shaping is done. Robots and smart machines help make work faster and more accurate. These systems do repetitive jobs, lowering mistakes and making work safer. Companies using automation often save money in just two years. It can also increase productivity by up to 30%.

Smart manufacturing goes beyond basic automation. It uses tools like artificial intelligence (AI) and lasers. These tools make work smoother and help with better decisions. For example, lasers with automation cut metal faster and more precisely. This improves product quality and saves time during production.

The Rise of 3D Printing in Metal Fabrication

3D printing, or additive manufacturing, is changing metal shaping. It helps create designs that were hard to make before. The market for metal 3D printing is growing quickly. By 2027, it could be worth $5,542.7 million, up from $1,800.2 million in 2022. This shows a yearly growth rate of 32.5%.

One big advantage of 3D printing is less material waste. Unlike cutting methods, it builds items layer by layer. This makes it better for the environment and supports green practices. Also, 3D printing speeds up making new products. This helps companies get their products to customers faster.

IoT Integration for Enhanced Efficiency

The Internet of Things (IoT) is improving metal shaping by connecting machines. IoT devices share data in real-time to check how machines are working. This helps predict repairs and reduces downtime, saving money.

For example, smart factories use IoT to plan work better and keep quality high. Companies like Ameritex use IoT to avoid accidents, cut waste, and improve processes. Using IoT makes work more efficient and helps businesses stay ahead in metal shaping.

Sustainability and Eco-Friendly Practices

Making metal products in a way that helps the planet is important. Businesses can use eco-friendly methods to save energy and reduce waste. This helps the environment and makes customers like your company more. People today prefer brands that care about nature.

Using recycled materials is one way to be sustainable. Many companies now use scrap metal to make new items. This reduces the need to dig for raw materials, saving natural resources. Energy-saving machines also help lower pollution. These machines use less power but still work efficiently.

Cutting down on waste during production is another key step. Older methods often create extra material, but new tools like 3D printing and lasers are more exact. These tools use only what’s needed, reducing waste and saving money.

🌱 Tip: Using solar or wind power can make your business even greener.

By choosing eco-friendly methods, you help the planet and show leadership in responsible manufacturing.

Workforce Challenges and Skill Development

Finding skilled workers for metal shaping is tough. About 75% of companies say hiring and keeping workers is hard. Retiring older workers makes this problem worse, leaving fewer experts in the field.

Workforce Problem | What It Means |

|---|---|

Worker Shortages | Hard to find and keep skilled employees. |

Retiring Workers | Older workers leaving creates a lack of experience. |

Tech Skills Gap | Workers don’t know how to use new tools. |

Career Awareness | Young people don’t know about jobs in metal shaping. |

Hiring Struggles | Changing job trends make recruiting harder. |

Training programs can help solve these problems. Teach workers to use modern tools like robots and IoT devices. This prepares them for today’s manufacturing needs. Offering good pay and benefits also attracts new workers.

You can also show young people the benefits of working in metal shaping. Partner with schools to introduce students to the industry. Solving these challenges ensures your team is skilled and ready for the future.

Technological Innovations Shaping the Future

Robots and AI in Metal Shaping

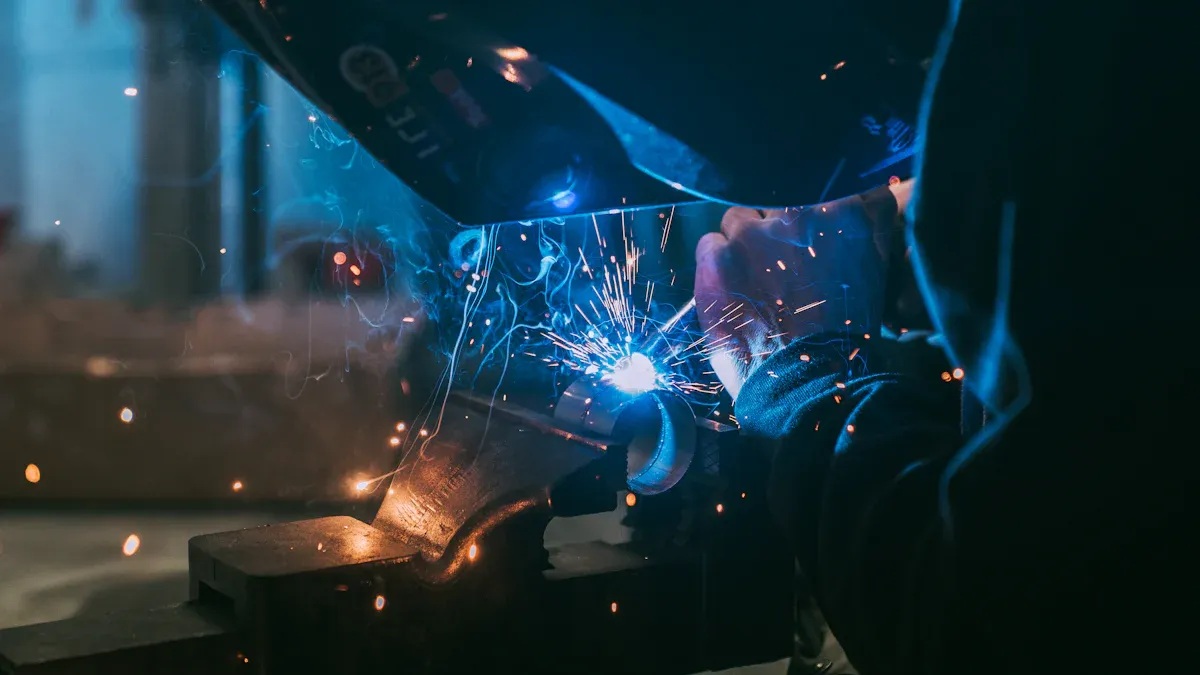

Robots and AI are changing how metal shaping is done. Robots do tasks like cutting and welding quickly and accurately. This lowers mistakes and keeps quality steady. AI systems study data instantly, helping you make better choices.

Automation also makes workplaces safer. Robots handle dangerous jobs, keeping workers safe from harm. For example, robotic welders give great results while reducing risks. Companies using these tools finish work faster and spend less money.

🤖 Did You Know? Automation boosts efficiency by 30% and cuts accidents a lot.

Feature | What It Does |

|---|---|

Automation Use | Improves accuracy and safety in metal shaping. |

Robotic Welding | Produces steady quality and speeds up production. |

Safety Boost | Lowers injuries by automating risky tasks. |

New Materials and Their Uses

The future of metal shaping depends on new materials. These include special alloys and mixes made for modern needs. These materials are stronger, last longer, and resist damage better.

For example, airplane makers use light alloys to save fuel. Car companies use materials that improve performance and lower weight. These new materials help make items that are stronger and better for the planet.

Technology | Advantages |

|---|---|

Advanced Materials | Stronger, longer-lasting, and better against wear and tear. |

Additive Manufacturing | Makes complex shapes with little waste. |

Using advanced materials helps you stay ahead and meet the need for better products.

Mixed Manufacturing Methods

Mixed manufacturing blends additive and subtractive techniques. This method makes detailed parts with fewer machines. For example, 3D printing creates designs, and CNC machines polish them.

This is great for industries needing custom or small-batch items. Car and gadget makers save money by making unique parts this way. Mixed manufacturing also cuts waste, making it better for the environment.

Process | Benefits |

|---|---|

Mixed Manufacturing | Combines 3D printing and CNC for better results. |

Using mixed methods helps you make custom items and improve production.

Predictive Analytics and Data-Driven Processes

Predictive analytics is changing how metal shaping is done. It uses data to find problems early and improve work. This helps spot patterns, avoid equipment issues, and work better. By studying past and live data, you can save time and boost output.

For example, tools for predictive maintenance stop costly machine failures. These tools check machines and warn you before something breaks. This avoids sudden stops and keeps work running smoothly.

Company Type | Tool Used | Improvement Achieved |

|---|---|---|

Car Maker | Embedded Analytics | 15% more work done |

Electronics Maker | Embedded Analytics | 12% faster production |

Steel Maker | Predictive Maintenance | 53% fewer sudden stops |

Embedded analytics tools also help make work better. They show where problems slow things down and help fix them. For instance, car makers improved work by 15% using these tools. Steel makers had 53% fewer sudden stops, proving how useful predictive analytics is.

Using data-driven methods helps you stay ahead of others. Predictive analytics makes work faster and keeps product quality steady.

Digital Twins and Simulation Technologies

Digital twins are changing how metal products are designed and tested. A digital twin is a computer copy of a real object or system. It lets you test how things will work in real life. This helps find problems early, saving time and materials.

For example, digital twins can test how strong a new metal is. Instead of making many samples, you can test ideas on the computer. This cuts waste and speeds up creating new designs.

Simulation tools also help improve how factories work. By making virtual models of your processes, you can find and fix problems. This keeps work smooth and meets today’s industry needs.

💡 Tip: Digital twins can lower costs and make products better.

Using digital twins and simulations helps you create faster and smarter. These tools keep you competitive in the fast-changing world of metal shaping.

Industry Impacts

Automotive Sector: Lightweight Materials and Precision

Car makers now use lightweight materials to save fuel and cut pollution. Materials like aluminum and magnesium help make cars lighter. These materials also improve how cars perform and keep passengers safer.

🚗 Fact: Lighter cars use less fuel, which is better for the planet.

Precise metal shaping is very important for making car parts. Tools like lasers and robots make parts with fewer mistakes. This helps create safer and more dependable vehicles. As electric cars become more popular, the need for light and precise parts will grow. This will change how metal shaping is done in the future.

Aerospace: Advanced Alloys and Complex Geometries

Airplane makers use special alloys to make strong and light parts. Materials like titanium and carbon composites are great for tough conditions. These materials keep planes light and save fuel on long trips.

Metal shaping tools also help make tricky shapes needed for airplanes. 3D printing allows for designs that were hard to make before. This new way of working improves how planes perform and cuts down on wasted materials. It also supports the industry's goal to be more eco-friendly.

Construction: Modular Fabrication and Sustainability

Building projects are changing with modular fabrication. This means making parts in factories and putting them together on-site. It speeds up building by 50% and causes less mess at the site.

Report Title | Key Findings |

|---|---|

MBI 2024 Report | Modular building helps Canada's housing market grow. |

The Sustainability of Modular Construction | 88% of builders say it cuts waste a lot. |

How Modular Construction Drives Productivity | Modular methods make projects finish twice as fast. |

Being eco-friendly is also a big focus in building. Modular fabrication uses resources wisely and creates less waste. As more people care about the planet, modular building will become even more important for the future of metal shaping.

Energy Sector: Efficiency and Durability in Equipment

Metal shaping is key to making energy tools better and stronger. As people want more green energy, new shaping methods are changing this field.

Modern tools like digital twins help check and improve work instantly. This keeps machines working their best and saves energy. Stronger metals and mixes are also used more now. These materials help machines last longer and handle tough jobs like heat or heavy use.

🌍 Tip: Using old metals again saves resources and cuts pollution.

Many factories now use solar or wind power to run. This change lowers the use of oil and gas and supports global green goals.

Benefits of new metal shaping in energy:

Saves resources by reusing old metals.

Cuts pollution with green practices.

Makes tools stronger with better materials.

Boosts efficiency using tools like digital twins.

By using these new ideas, you can make energy tools that work well and are good for the planet. This helps both your business and the Earth in the long run.

Electronics: Miniaturization and High-Performance Components

The electronics world grows with new ideas, and smaller parts lead the way. Tiny parts help make gadgets that are easy to carry, work better, and look cool. For example, small parts improve signals, making devices faster and stronger.

📱 Did You Know? Smaller parts mean bigger batteries for longer use.

Small electronics also make smart tech like AI and robots better. Tiny sensors help planes see better, and small cameras improve navigation. These changes make gadgets smarter and more useful.

Why smaller parts matter in electronics:

Easy to carry, boosting demand for smart gadgets.

Costs less because fewer parts are needed.

Uses less power, saving energy.

Works faster with shorter signal paths.

By focusing on smaller parts, you can make gadgets that people love. This not only makes your products better but also helps you stay ahead in the market.

Metal shaping tools are changing industries by making work faster and greener. Robots, new materials, and smart tools like predictive maintenance have improved how things are made.

Improvement Type | How It Helps Industries |

|---|---|

Robot Use | Speeds up work and lowers worker costs |

Stronger Materials | Makes items lighter and tougher |

Green Practices | Cuts waste and saves energy, helping the planet |

Smart Tools | Tracks machines and fixes problems early |

Custom Designs | Makes special items and lowers storage costs |

To stay ahead, use tools like lasers, 3D printers, and eco-friendly methods. Higher material prices and the need for custom items show why being flexible is key.

Smart tips for future success:

Use green methods to save energy and cut waste.

Try new tools for better accuracy and faster work.

Make small batches to meet special customer needs.

The future of metal shaping relies on new ideas and caring for the Earth. By using these methods, you can lead in making better products while helping the planet.

FAQ

What does automation do in metal fabrication?

Automation makes work faster and more accurate. Robots handle simple tasks and lower mistakes. This keeps workers safe and saves time. It also helps make better products and focus on new ideas.

How does 3D printing help metal fabrication?

3D printing makes tricky designs with less waste. It builds items step by step, using fewer materials. This speeds up testing and gets products to customers faster. It’s good for the planet and allows for unique designs.

Why is being eco-friendly important in metal fabrication?

Eco-friendly methods protect nature and save resources. Using recycled metals and energy-saving machines cuts waste and pollution. Customers like brands that care about the planet, which can grow your business.

What are digital twins, and why are they useful?

Digital twins are computer copies of real things. They help test ideas without wasting materials. You can fix problems early and make work better. These tools save money and keep you ahead of others.

How can you solve worker problems in metal fabrication?

Teach workers how to use new tools like robots. Work with schools to show students job options. Offer good pay and benefits to keep skilled workers happy.