What Are the Different Types of Welding Processes and Their Benefits

What Are the Different Types of Welding Processes and Their Benefits

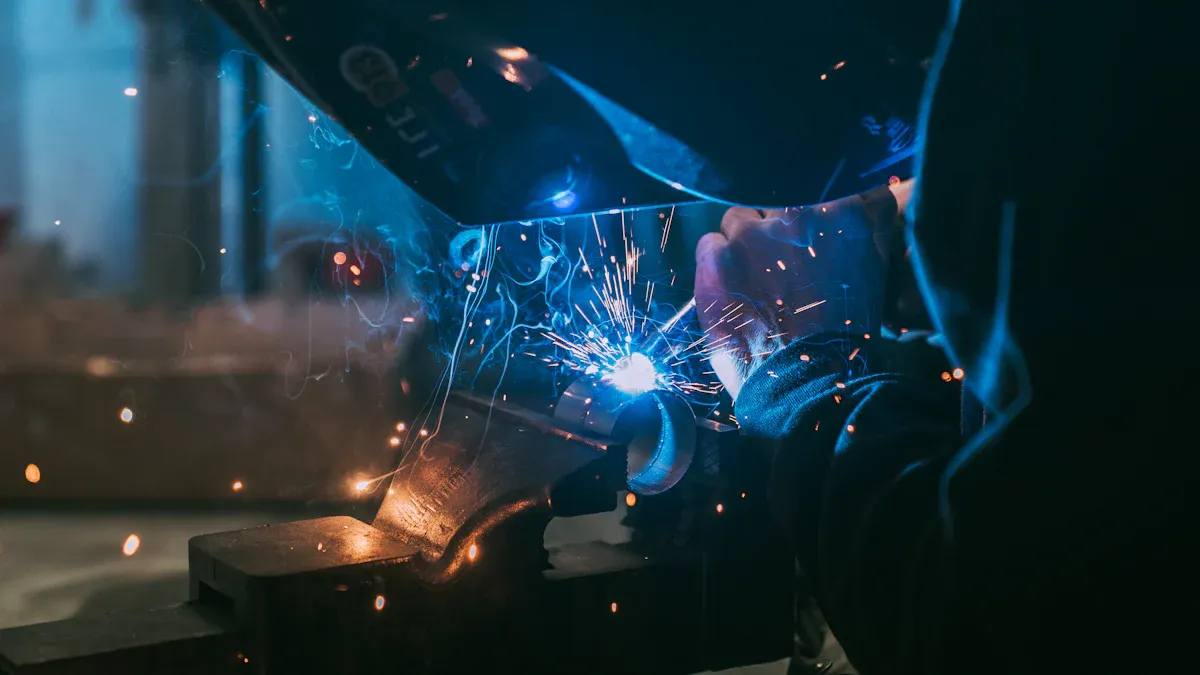

Welding is important for connecting metals in many industries, particularly in metal welding. It is used in car making, building construction, and shipbuilding. For example:

MIG welding joins car frames and body parts.

Arc welding makes strong steel beams and columns.

TIG welding makes accurate and strong joints for key parts.

These metal welding methods help make metalwork fast and flexible.

Key Takeaways

MIG welding works quickly and well, great for big jobs like making cars.

TIG welding is precise and neat, best for jobs needing accuracy, like in airplanes.

Stick welding is cheap and works outside, good for building projects.

Common Types of Welding Processes

MIG Welding (Metal Inert Gas)

MIG welding is a common method in factories and construction. It uses a wire as an electrode and gas to protect the weld. This process is fast and works well for big projects. For example, it is used to make car frames and metal parts.

MIG welding has many benefits in industries. It saves materials, reduces mistakes, and works efficiently. These features help save money and improve work speed. Tools like deposition rates track its performance and make it better.

TIG Welding (Tungsten Inert Gas)

TIG welding is a precise way to join metals. It uses a tungsten electrode that does not melt. This method is great for clean and strong welds. It is often used in aerospace and car-making where accuracy matters.

TIG welding has technical benefits. The gas keeps the weld clean and free of defects. It can join different materials and thicknesses. This makes it perfect for projects needing strong and exact welds.

Stick Welding (Shielded Metal Arc Welding)

Stick welding, or SMAW, is a flexible and trusted method. It uses an electrode with a coating to make the weld. This process is popular in construction, especially outdoors.

Stick welding is affordable and works well in remote areas. It does not need extra gas, so it's good for windy places. It creates strong joints that last a long time. This method is great for fixing and building structures safely.

Flux Cored Arc Welding (FCAW)

Flux cored arc welding, or FCAW, is partly automatic. It uses a wire with flux inside, so no extra gas is needed. This makes it a cheaper option. FCAW is useful for outdoor jobs and heavy work like shipbuilding.

This method is fast because of its continuous wire feed. It is simple to learn, so beginners can use it easily. FCAW works well in windy areas, making it very practical. It is a favorite for projects needing speed and low costs.

Advanced Types of Welding Processes

Plasma Arc Welding

Plasma arc welding is very accurate and uses a plasma torch. The torch creates a focused arc for detailed and careful work. This method is great for small, precise tasks. Industries like aerospace and electronics use it for high-quality results.

Benefits of plasma arc welding:

Better control for tricky and detailed welds.

Deep welds and fast work improve productivity.

Cleaner welds with fewer mistakes for stronger results.

This process is best for jobs needing accuracy and speed.

Electron Beam Welding

Electron beam welding uses electrons to join materials in a vacuum. The vacuum stops contamination, making the weld perfect. It is used in industries like cars and airplanes for top-quality work.

With no weld failures and high precision, it's ideal for perfect projects.

Laser Beam Welding

Laser beam welding is a modern and advanced welding method. It uses a strong laser to melt and join metals quickly. This method is very fast and accurate, used in cars and medical tools.

Laser welding has many benefits:

It makes deep, narrow welds with little distortion.

The process is automated, saving time and money.

It works with many materials like metals and alloys.

Laser welding is great for jobs needing speed and precision.

Gas Welding (Oxy-Acetylene Welding)

Gas welding, or oxy-acetylene welding, is one of the oldest methods. It uses a flame from oxygen and acetylene gas to melt metals. This method is flexible and good for repairs and making things.

Gas welding is still useful for small jobs and portable needs.

Knowing about different welding methods helps you pick the best one. Common types like MIG and TIG welding are useful. Advanced methods, such as laser and electron beam welding, have special benefits. Stick welding and flux cored arc welding are strong and work well in tough places.

These methods also affect costs and production. Look at these examples:

Picking the right welding method can save money and time. It also helps make strong and high-quality metal products.

FAQ

What makes MIG and TIG welding different?

MIG welding uses a wire that melts to join metals. TIG welding uses a tungsten rod that doesn't melt for clean welds.

Why is arc welding often used in construction?

Arc welding makes strong joints that last a long time. It works on many metals and is good for outdoor jobs.

Can laser welding work on all materials?

Laser welding works on most metals and alloys. But it's not great for shiny or very thick materials.